Choosing the correct lockout device

Why is choosing the correct lockout device important?

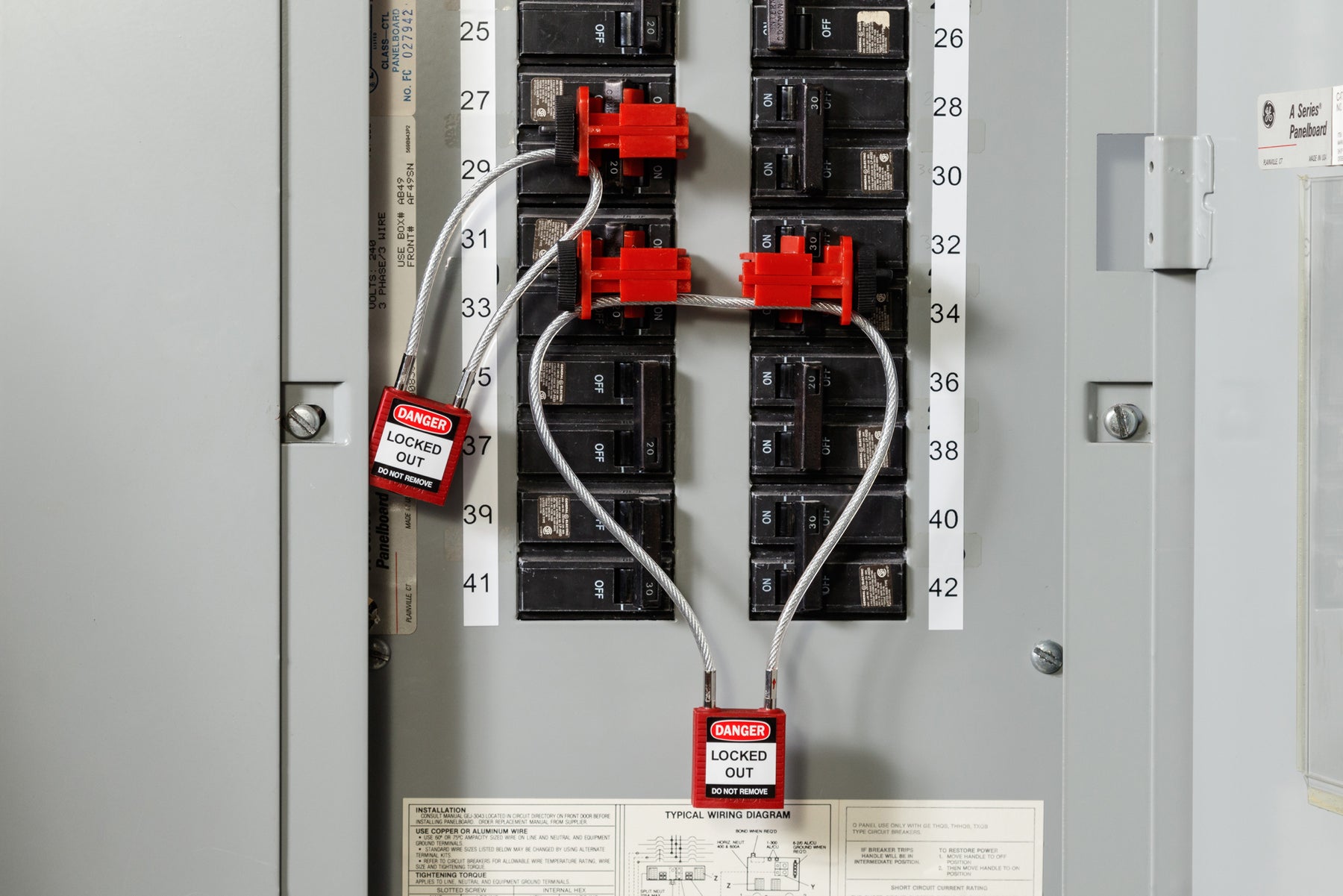

When it comes to ensuring workplace safety, choosing the correct lockout device is crucial. Lockout devices are used to prevent the accidental release of hazardous energy during maintenance or repair work on machinery or equipment. Using the wrong lockout device can lead to serious accidents and injuries. So, how do you choose the right lockout device?

What factors should you consider?

1. Equipment type: Different lockout devices are designed for specific types of equipment. Consider the machinery or equipment you need to lock out and select a device that is compatible with it.

2. Energy source: Identify the energy source that needs to be isolated. Lockout devices are designed to fit different types of energy sources such as electrical, hydraulic, pneumatic, or mechanical. Ensure that the device you choose can effectively isolate the specific energy source.

3. Size and dimensions: Lockout devices come in various sizes and dimensions. It is important to select a device that fits securely and snugly on the equipment you are working on. A loose or ill-fitting lockout device may not provide adequate protection.

4. Durability: Look for lockout devices made from durable materials that can withstand the conditions of your workplace. They should be able to resist corrosion, extreme temperatures, and physical impact.

Are there any industry standards to follow?

Yes, there are industry standards that provide guidelines for choosing and using lockout devices. The Occupational Safety and Health Administration (OSHA) in the United States, for example, has specific regulations regarding lockout/tagout procedures. Familiarize yourself with these standards and ensure that the lockout device you choose complies with them.

What are the benefits of using the correct lockout device?

1. Enhanced safety: Using the correct lockout device minimizes the risk of accidental energy release, protecting workers from potential injuries or fatalities.

2. Compliance with regulations: By using the appropriate lockout device, you ensure compliance with safety regulations, avoiding penalties and legal issues.

3. Increased efficiency: The right lockout device allows for efficient and effective maintenance or repair work, reducing downtime and improving productivity.

4. Peace of mind: Knowing that you have chosen the correct lockout device gives you peace of mind, knowing that you have taken the necessary steps to protect yourself and your colleagues.

Conclusion

Choosing the correct lockout device is a critical step in ensuring workplace safety. Consider the equipment type, energy source, size, and durability when selecting a lockout device. Familiarize yourself with industry standards and regulations to ensure compliance. By using the right lockout device, you enhance safety, comply with regulations, increase efficiency, and gain peace of mind.